In the world of technical rubber moulding, mould cleaning is often underestimated or postponed. Some consider it a secondary activity, to be carried out only when obvious production problems arise.

But is that really the case? In this article, we debunk the main myths about mould cleaning and explore the real impact this practice has on productivity, product quality, and business costs.

“As long as the mould works, there’s no need to clean it”

This is one of the most common mistakes.

Even if a mould seems to be working properly, invisible residues of material, release agents, and contaminants can accumulate over time. This progressively compromises the quality of the moulded parts and increases the risk of surface defects, flash, and scrap.

Regular cleaning prevents problems before they become visible, keeping the mould in optimal condition and ensuring consistent, uninterrupted production.

“Cleaning moulds is a waste of time”

In reality, the opposite is true.

Preventive maintenance, which includes regular cleaning, significantly reduces machine downtime caused by failures or more complex corrective interventions.

Moreover, the time spent on scheduled cleaning is much less than the time and costs involved in restoring a damaged mould.

Mould cleaning is an essential part of predictive maintenance, fundamental for reducing costs over the medium to long term.

“All cleaning methods are the same”

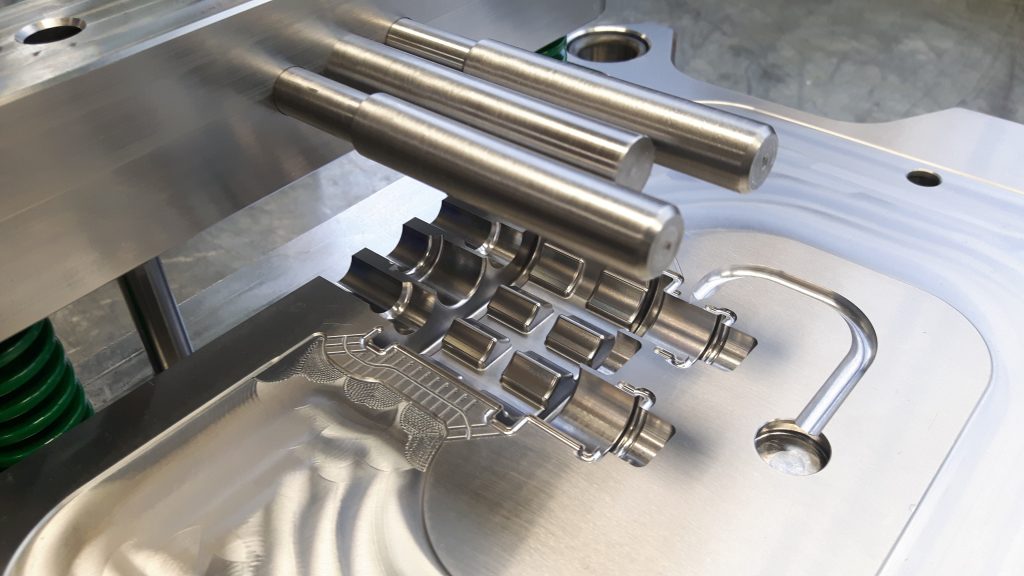

There are several methods for cleaning a mould, but not all are suitable for every situation. The choice depends on the material, the type of contamination, and the geometric complexity of the mould.

Choosing the right method makes all the difference in terms of effectiveness, time, and surface preservation.

Mould cleaning for technical rubber articles and O-Rings: benefits

Proper mould cleaning offers several important advantages:

- Increased service life of the mould

- Improved quality of the moulded product

- Reduced scrap and reworking

- Fewer machine downtimes

- Greater production efficiency

Mould cleaning is not a detail: it is a key step for anyone aiming for reliable, efficient, and long-lasting production. Ignoring it exposes you to risks, unexpected costs, and a decline in product quality.

Let’s dispel any doubts: mould cleaning is truly necessary, and choosing the right technique is the first step towards smarter production management.

Click here to download our free guide on how to choose the right mould cleaning method.