The problem of moulded articles not detaching from moulds is a common concern among customers.

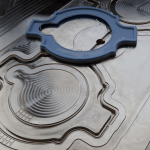

While chrome-plating has been effective in addressing this issue, it also results in a smooth and glossy surface.

Consequently, with some part geometries, a suction cup effect is created between the mould’s surface and the moulded pieces.

The solution?

Combining chrome-plating with a satin finish. In fact, in most cases, satin finishing makes detaching moulded pieces easier.

This treatment is essential on moulds to be used with silicon, Viton, peroxide-cured rubber, and all sticky compounds, as it eliminates the “suction cup” effect, enhancing the detachment of rubber.

Chrome-plating remains the most widely used treatment for rubber part moulds. Its aesthetic and functional characteristics offer several benefits, including:

- Customizable surface: Chrome plating allows you to obtain a shiny or matt surface depending on your needs and the type of compound used.

- High mechanical performance: High resistance to abrasion, corrosion and oxidation, helping to extend the life of the rubber seal mould up to three times.

- Ease of removal of the piece: Chrome plating simplifies the detachment of the piece, improving the efficiency of the production process and reducing waste.

- Easier maintenance: Cleaning and maintenance of the mould becomes easier, as chrome plating reduces the accumulation of residues, helping to keep the surface intact and cleaner.

To achieve optimal quality and enhance the efficiency of the production process, careful consideration must be given to selecting appropriate surface or heat treatments for your mould. For personalized assistance or specific inquiries, please don’t hesitate to reach out to our dedicated team at info@ocs-stampi.it.