Recently, a French customer of ours (a subcontractor in the automotive sector for a well-known automotive company) contacted us.

PROBLEM AND CUSTOMER NEEDS

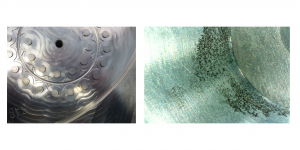

Our customer noted some defects on the rubber technical articles from their production and, consequently, has requested that we check the mould. The mould had a damaged surface near the cavities and the customer asked us what could be the cause of these defects:

They needed a quick and effective solution in order to be able to produce more defect-free technical design pieces. However, they did not want to invest their budget in a mould that could potentially have the same defect as the previous one. Their priorities were:

- A quick solution in order to be able to rapidly assemble the mould in the press and start a second moulding cycle;

- A solution that avoided the recurrence of this defect.

CAUSE ANALYSIS

We made an in-depth analysis of the mould and of the technical rubber articles. The mould showed darker spots or stains which were actually areas of micro-corrosion caused by some aggressive components contained in the compound. Moreover, the mould was not chrome-plated and, as a consequence, it was unprotected. This is the reason why the rubber has slipped into the corrosion cracks leading to the result in the second photograph. To sum up, the two causes are:

- The lack of mould cleaning after the first moulding cycle;

- The absence of a chrome-plating treatment which would have better protected the mould from the rubber’s corrosive agents.

SOLUTION

In this case the damage was irreparable and, consequently, the mould for the rubber technical article was completely remade. We have operated, considering the absolute priority of the customer, following this process:

- Complete remaking the mould in a short time to give the customer the opportunity to start production again as soon as possible.

- Chrome-plating of the mould in order to protect the mould surface from the risk of future corrosion.

- The OCS Service technicians trained the customer on two topics:

-

- mould maintenance/cleaning

- the importance of chrome-plating.

Our client has benefited from a personalised consultation supported by e-books created especially by our team’s experts on the subject of chrome plating and mould cleaning.

THE FEEDBACK

In conclusion, our French client was very surprised by the flexibility and speed of our diagnostic and fault-correcting service. Currently the mould, built by us, allows him to mould technical rubber articles without any defect. Through this case we have shown again that focusing on the customer is the winning solution to create a product and offer an optimum service. Furthermore, the study of the causes of the customer’s issue allowed us to provide him with an immediate solution. Indeed, by training the customer on the subject of mould maintenance and cleaning, we have given him the opportunity to prevent the same problem in the future. Have you ever seen technical rubber articles or O-rings that are defective due to a worn-out mould? If you would like to find out how to best maintain your moulds and prevent any defects on your technical rubber articles, contact us at info@ocs-stampi.it