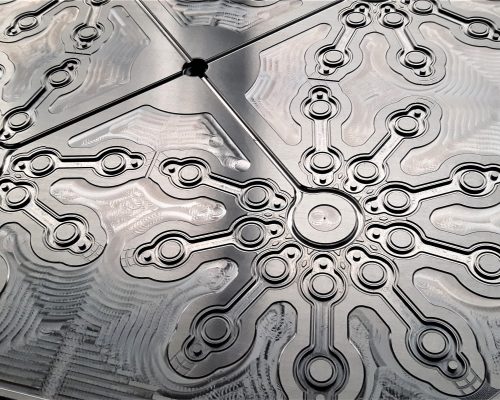

Sandblasting is one of the most advanced methods for surface cleaning of O-Rings moulds and/or technical rubber items, because it is convenient in terms of time. A mould can be cleaned with different types of microspheres: silica sand is the most used one but it is also possible to use quartzite powder, sodium bicarbonate, corundum or silicon carbide.

ARE THESE METHODS RISKY?

Sandblasting is an effective method but, extensive use can ruin both the chrome plating layer as well as the cavities edges of the mould. The harder the grit used, the more incisive the sandblasting on the hard surfaces will be. To minimize or even eliminate this “side effect” and to preserve better the surface of the mould it is better to choose a less aggressive aggregate, such as plastic or bicarbonate.

If, instead, you prefer to use the sandblasting method with glass micro-granules we suggest you to follow these parameter:

- Use sand granules in size 40/70 (very fine) with air pressure not be greater than ¾ bar.

Determining factors for an excellent result are the air pressure and the distance of the pistol from the nozzle.

IS THERE A SIMILAR METHOD BUT LESS AGGRESSIVE?

Yes! The best alternative is the cryogenic cleaning. This type of cleaning, also known as “dry ice cleaning“, uses dry ice pellets and compressed air. This mixturem hitting the surface to be cleaned, brings to detachment of the incrustations and cleaning of the fumes. The ice pellets are accelerated up to 300 m / s and come out on the surface with a special pistol at a temperature of -79 ° C.

WHY TO CHOOSE THE DRY ICE

Dry ice cleaning makes it possible to work directly on the injection maching without having to remove the mould and does not compromise the chrome plating treatment.

Moreover, compared to other methods, it is very convenient in terms of time. In fact, cleaning can be carried out quickly and effectively without having to dismantle the mould.

These are the main methods for surface cleaning of the moulds, perfect if you produce technical articles in rubber. However, please remember that it is necessary to remove dirty waste. Read our next article to find out how!